Arc Flash PPE Category Explained

Understanding the Arc Flash PPE Category is an essential component of electrical worker safety. Electrical workers must wear and be properly trained in the safe use and application of appropriate personal protective equipment (PPE) for the possible electrical hazard with which they may face. Arc Flash PPE Category has been designed by NFPA as a way for electrical workers to determine what level of protective clothing to wear, depending on their risk hazard exposure.

Examples of Arc Flash PPE could include a hard hat, face shield, flame resistant neck protection, ear protectors, flame retardant arc flash suit, insulated rubber insulating gloves with leather protectors, and insulated leather footwear. Ar clothing must meet the requirements as shown in the latest edition of NFPA 70E. Arc Flash PPE, sufficient for protection against the potential electrical flash, is required for every part of the body. The selection of the required thermal arc rated ppe depends on the incident heat energy level at the point of work.

The common distance used for most of the low voltage incident energy measurement research and testing is at 18 inches from the arcing fault source. So what energy does a body part experience that is closer to the arc fault than 18 inches? The closer to the arcing fault, the higher the incident energy and blast hazard. This means that when the flash protection analysis results are calculated at 18 inches from the arc fault source, the incident energy and blast energy at the point of the arc fault are considerably greater. Said in another way, even if the body has sufficient Arc Flash PPE for an 18″ working distance, severe injury can result for any part of the body closer than 18″ to the source of the arc.

Advances in arc flash kits have definitely improved the arc-flash clothing options available to workers. It was not all that long ago – the 1980s – that the choice of flash protection was extremely limited, and few employers even had a policy on flash clothing. Today there are a dozen or so brand names of Arc Flash PPE, with some brands providing different fabrics ranging from five to 13 ounces per square yard fabric weight. These fabrics are available in an array of colors, weaves, and textures. As with all safety equipment, arc kit is of no use to anyone unless it is being used at the time of an arc flash. This article addresses available fabrics to be worn by workers and the associated definitions of arc flash terms.

Definitions Arc Thermal Performance Value (ATPV): This value is presented in calories per square centimeter and represents the maximum capability for arc-flash protection of a particular garment. This rating also applies to fabrics. However, a garment made from more that one layer of arc-flash rated fabric will have a calories per square centimeter rating greater than the sum of the ATPV ratings of the original fabrics. The calories per square centimeter rating of most arc-flash protective suits, coveralls, and coats is commonly sewn into the fabric in large letters on the outside of the garment. Flame Resistant (FR): “Flame resistant” can describe a fabric naturally resistant to burning but also can represent a material with special treatment applied to the fabric.

Occasionally, the letters FR are used to represent “flame retardant.” This can lead to some confusion because a flame-retardant treated fabric is flame resistant, but a flame-resistant fabric is not necessarily flame retardant. Flame Retardant: This term could be used to describe a fabric made up of a flammable fabric treated in such a way that it will provide arc-flash protection.

Fabric Weight: This is usually represented in one of two ways: ounces per square yard or grams per square meter. Both of these values essentially refer to the thickness of the fabric. The more ounces per square yard, the more material exists in the same square yard of fabric.

Heat Attenuation Factor (HAF): This is the amount of heat blocked by the fabric. Even though a fabric may be 100 per cent flame resistant, that does not mean it will block all of the heat to which it is exposed. An HAF of 85 percent means that it will block 85 percent of the heat the fabric encounters. This applies to a short burst of heat – typically less than one second. In the event of prolonged heat exposure, the HAF would be much lower.

Calories per Centimeter Squared: This is a number identifying the amount of energy that can be delivered to a point at a particular distance from an explosion. Once this value is known, the ATPV rating of the required for work at that distance from the potential flash hazard is also known.

Energy Break-Open Threshold (EBT): Primarily, this addresses the physical strength of the fabric with respect to thermal energy and at what value the fabric will fail.

Personal Protective Equipment: This term is primarily used to describe all Arc Flash PPE used by personnel to protect personnel. This includes fall protection, confined space, electrical hazards, minimum arc rating, etc.

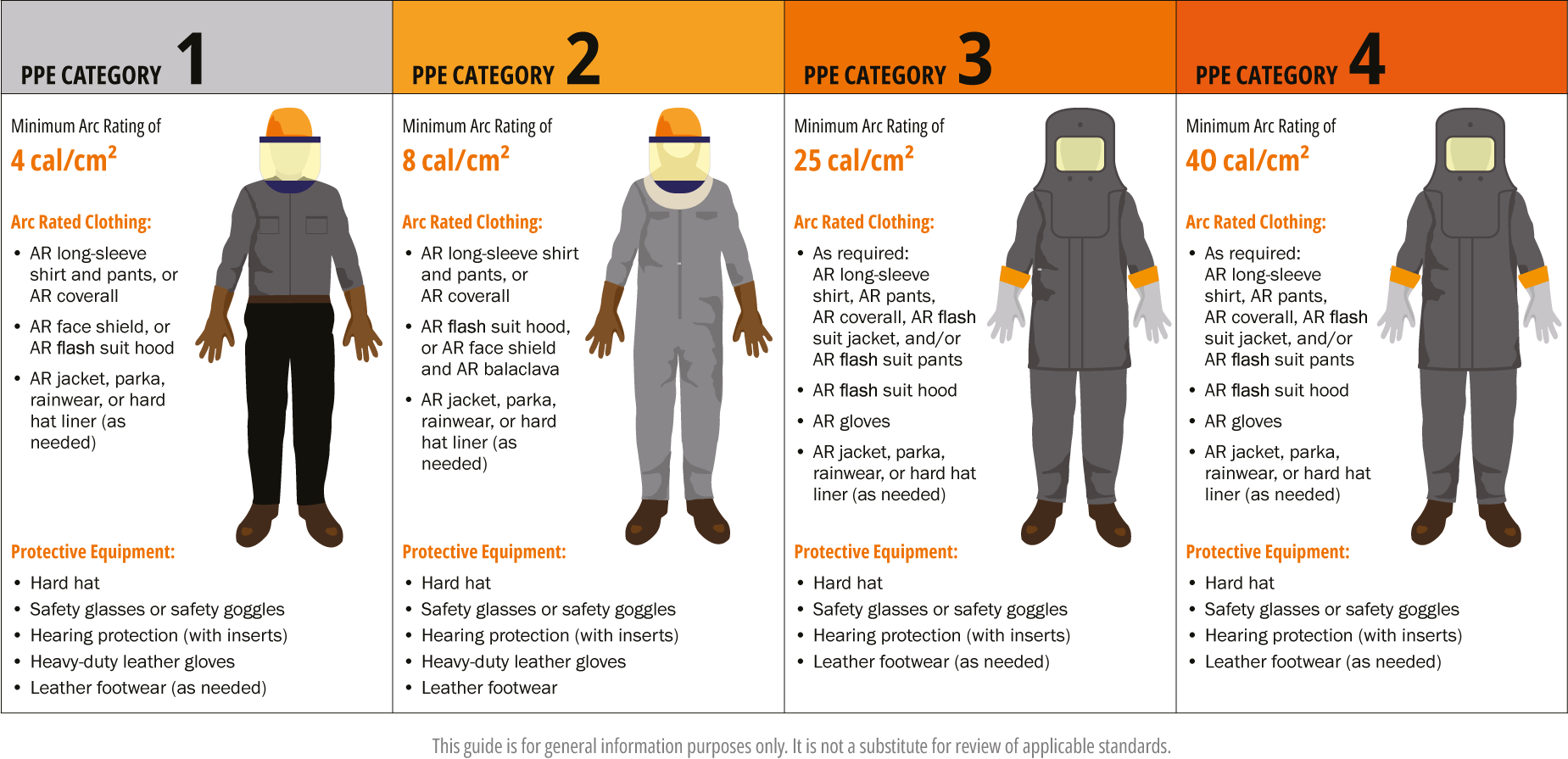

Hazard Risk Category (HRC): This is an NFPA 70E rating of exposure levels for particular types of equipment. The values range from zero to four, with a zero HRC with a zero HRC not requiring any ATPV-rated. The minimum ATPV rating for Categories One through Four are as follows:

The common distance used for most of the low voltage incident energy measurement research and testing is at 18 inches from the arcing fault source. So what energy does a body part experience that is closer to the arc fault than 18 inches? The closer to the arcing fault, the higher the incident energy and blast hazard. This means that when the flash protection analysis results are calculated at 18 inches from the arc fault source, the incident energy and blast energy at the point of the arc fault are considerably greater. Said in another way, even if the body has sufficient Arc Flash PPE for an 18″ working distance, severe injury can result for any part of the body closer than 18″ to the source of the arc.

Advances in arc flash kits have definitely improved the arc-flash clothing options available to workers. It was not all that long ago – the 1980s – that the choice of flash protection was extremely limited, and few employers even had a policy on flash clothing. Today there are a dozen or so brand names of Arc Flash PPE, with some brands providing different fabrics ranging from five to 13 ounces per square yard fabric weight. These fabrics are available in an array of colors, weaves, and textures. As with all safety equipment, arc kit is of no use to anyone unless it is being used at the time of an arc flash. This article addresses available fabrics to be worn by workers and the associated definitions of arc flash terms.

Definitions Arc Thermal Performance Value (ATPV): This value is presented in calories per square centimeter and represents the maximum capability for arc-flash protection of a particular garment. This rating also applies to fabrics. However, a garment made from more that one layer of arc-flash rated fabric will have a calories per square centimeter rating greater than the sum of the ATPV ratings of the original fabrics. The calories per square centimeter rating of most arc-flash protective suits, coveralls, and coats is commonly sewn into the fabric in large letters on the outside of the garment. Flame Resistant (FR): “Flame resistant” can describe a fabric naturally resistant to burning but also can represent a material with special treatment applied to the fabric.

Occasionally, the letters FR are used to represent “flame retardant.” This can lead to some confusion because a flame-retardant treated fabric is flame resistant, but a flame-resistant fabric is not necessarily flame retardant. Flame Retardant: This term could be used to describe a fabric made up of a flammable fabric treated in such a way that it will provide arc-flash protection.

Fabric Weight: This is usually represented in one of two ways: ounces per square yard or grams per square meter. Both of these values essentially refer to the thickness of the fabric. The more ounces per square yard, the more material exists in the same square yard of fabric.

Heat Attenuation Factor (HAF): This is the amount of heat blocked by the fabric. Even though a fabric may be 100 per cent flame resistant, that does not mean it will block all of the heat to which it is exposed. An HAF of 85 percent means that it will block 85 percent of the heat the fabric encounters. This applies to a short burst of heat – typically less than one second. In the event of prolonged heat exposure, the HAF would be much lower.

Calories per Centimeter Squared: This is a number identifying the amount of energy that can be delivered to a point at a particular distance from an explosion. Once this value is known, the ATPV rating of the required for work at that distance from the potential flash hazard is also known.

Energy Break-Open Threshold (EBT): Primarily, this addresses the physical strength of the fabric with respect to thermal energy and at what value the fabric will fail.

Personal Protective Equipment: This term is primarily used to describe all Arc Flash PPE used by personnel to protect personnel. This includes fall protection, confined space, electrical hazards, minimum arc rating, etc.

Hazard Risk Category (HRC): This is an NFPA 70E rating of exposure levels for particular types of equipment. The values range from zero to four, with a zero HRC with a zero HRC not requiring any ATPV-rated. The minimum ATPV rating for Categories One through Four are as follows:

- Category One: five calories per square centimeter

- Category Two: eight calories per square centimeter

- Category Three: 25 calories per square centimeter

- Category Four: 40 calories per square centimeter